Vertical Type Multifunctional Single Nozzle Filling Machine

TECHNICAL PARAMETER

TECHNICAL PARAMETER

Vertical Type Multifunctional Single Nozzle Filling Machine

| Voltage | AV220V, 1P, 50/60HZ |

| Dimension | 460*770*1660mm |

| Filling Volume | 2-14ml |

| Tank Volume | 20L |

| Nozzle Diameter | 3,4,5,6mm |

| Configuration | Mitsubishi PLC |

| Air Consumption | 4-6kgs/cm2 |

| Power | 14kw |

Features

Features

-

- 20L double layer holding bucket, with mixing and oil heating.

- Driven by Servo motor, filling data can be setup in the touch screen.

- Filling capacity is controlled by piston cylinder’s volume.

- With foot pedal to give filling start on/off.

- Filling precision ±0.1g.

- With parameter storage function for different formular.

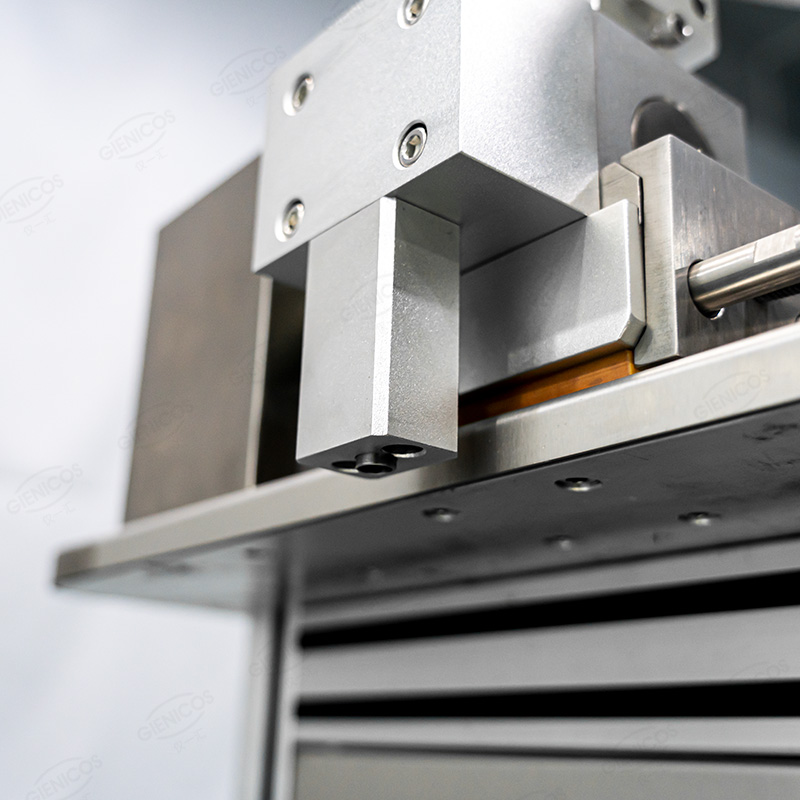

- Fast cleaning because of the newly designed valve set.

- Parts contacted with material adopts SUS316L.

- Frame is made of aluminum and SUS material.

Nozzle can be changed with different sizes.

Application

Application

- This machine is used for filling different viscosity materials and suitable for different sizes of vessel such as eyeshadow cream,lipgloss,lipstick,lip oil.

Why choose us?

Why choose us?

This vertical cosmetic filling machine reduces labor costs, saves space, reduces rent, etc., and can reduce the waste of raw materials.

Using the filling machine can simplify the manual process, and the operation is simple and easy to use.

Through mechanization, the hygienic environment inside the mechanical conveying system is very stable, which reduces the risk of contamination.

Through mechanization, the filling accuracy is increased and the operating rate is increased.

The production line can be adjusted. We can adjust the speed of the production line in the peak season and slow down the production line in the off-season.

Visualize the production process: it can improve efficiency, such as improving product safety and reliability, inventory and quality control.