Six Nozzle Lipbalm Machine with 2ML TO 100ML Hot Filling Production Line

|

Outer dimension |

Customized according to the room space |

|

Voltage of 6nozzle filler |

AC220V,1P,50/60HZ |

|

Voltage of cooling tunnel |

AC380V(220V),3P,50/60HZ |

|

Power |

17KW |

|

Filling Volume |

2-20ml, 20-50ml and 50-100ml by replacing pump |

|

Filling Preicison |

±0.1G to 0.2G |

|

Cooling Capacity |

5P |

|

Air supply |

0.6-0.8Mpa,≥800L/min |

|

Output |

Max 40pcs/min.(acc.to raw materials&mold quantity) |

|

Weight |

1200kg |

|

Operator |

2 persons |

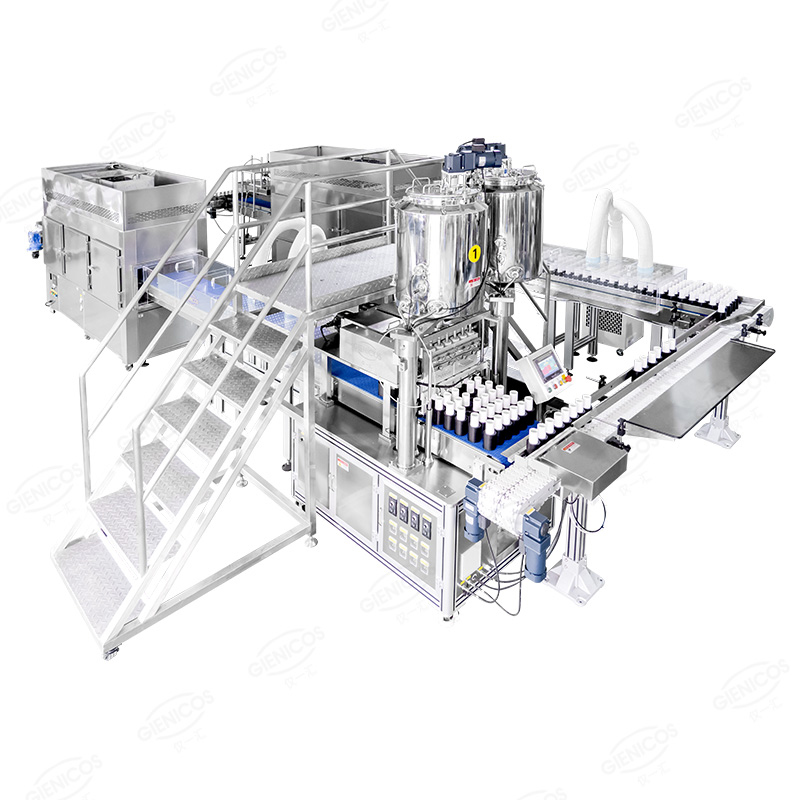

◆ Flexible and multi-usage for hot filling products.

◆ Temperature and stirring speed adjustable. Dual Temp.control for both bulk and oil.

◆ 2pcs 50L dual layer heating tank with mixing and heating function.

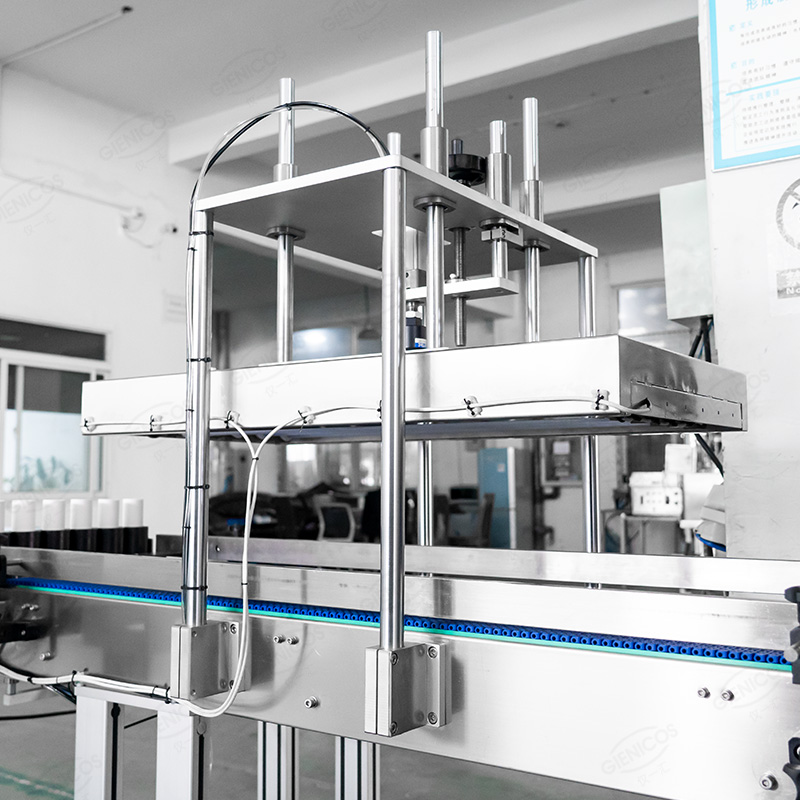

◆ Fill 6pcs simultaneously with 6 nozzles, diving nozzles with servo control.

◆ Piston filling system is driven by Servo motor with numerical control. Rotary valve is driven by air cylinder.

◆ Stirring device is driven by motor.

◆ Simple and precise operation by using colorful touch screen interface with numerical control in all aspects.

◆ Filling precision is ±0.1 to 0.2g.

Products such as lip balms, deodorants,hair wax, candles, and more are all filled into their respective containers as molten products, solidifying as they cool. With GIENICOS lip balm hot filling machine, your production line can handle the product quickly and efficiently, dispensing the correct amount of product into the lip balm tube, deo.stick tubes and candle containers etc.

With immense expertise and market knowledge in this domain, we have emerged as the leading manufacturer, trader and supplier of Lipbalm filling machine. This filling machine is appreciated among customers due to its less maintenance & easy installation. The offered filling machine is developed by our experts utilizing high quality of material & modern techniques. As well, we are giving this filling machine on numerous specifications so as to meet the demand of customers.

The whole filling system adopts fast connection to help end user do the fast cleaning and spares changing purpose. Piston pump fillig adopts servo driven for high precision filling. Diving nozzles are able to do bottom filling for six containers at one time.

Multi-stage design for the cooling with excellent cooling results is wonderful for different volume products. By working with direct filling, wax get shrink and we give the remelting function to achieve smooth surface. Customers are happy with the end products’ display, GIENICOS always aims to make the cosmetic machines not only the machines but the most important is to make a perfect cosmetic products. Contact us for more info.

润唇膏-300x300.png)