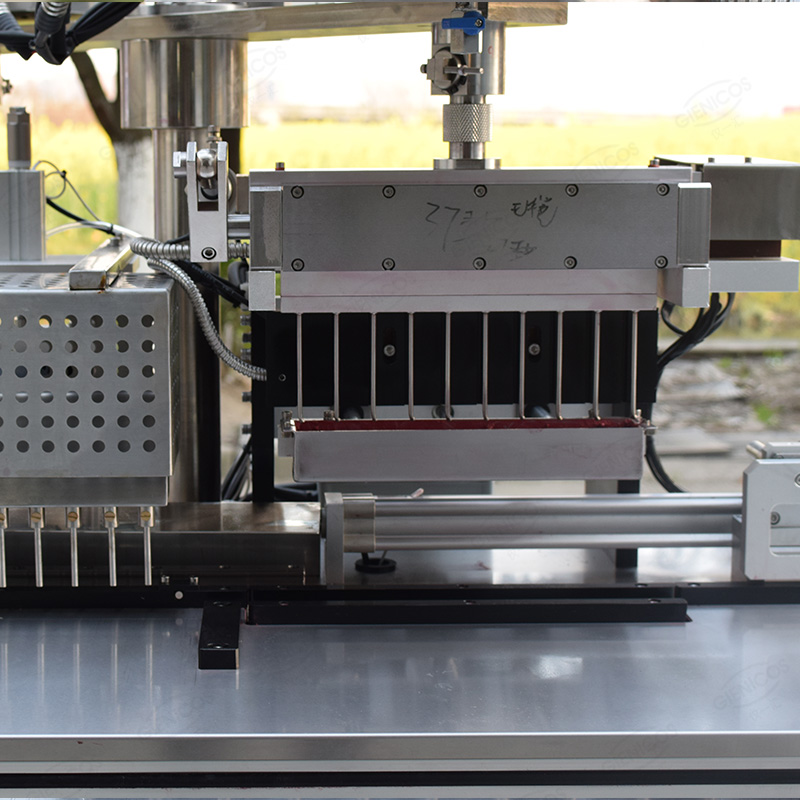

Servo Motor Mold Lifting 10 Nozzles Lipstick Preheating Filling Machine

| Outer dimension | 1300 x 1000 x 2180 mm (L x W x H) |

| Voltage | AC380V(220V), 3P, 50/60HZ |

| Power | 8KW |

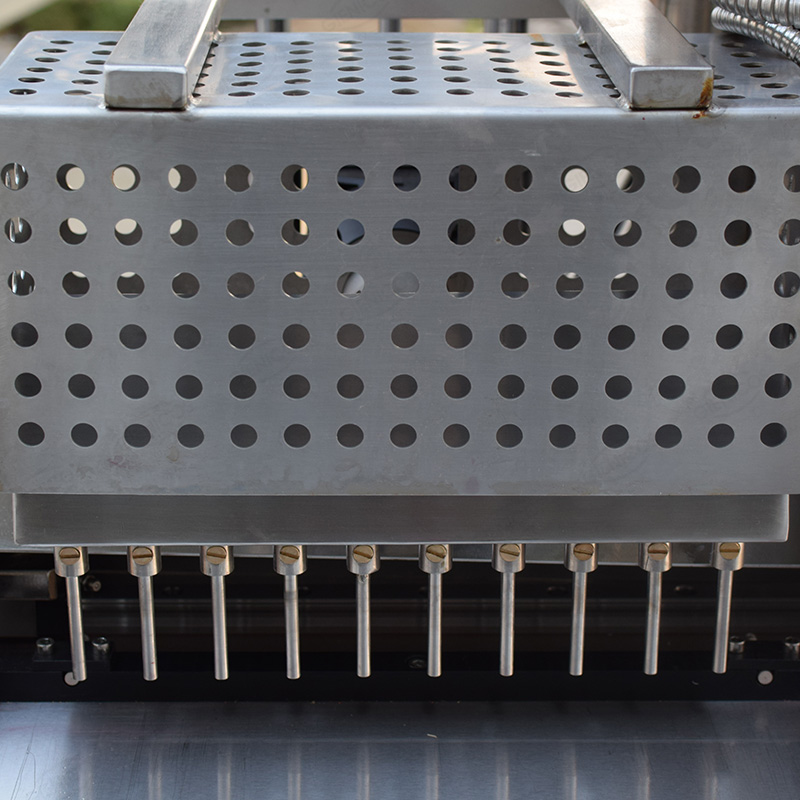

| Filling nozzle | 10 nozzles |

| Lipstick mold | Silicone rubber mold |

| Lipstick shape | Water Drop, Nail Drop, Moon Drop (According to product) |

| Air supply | 0.6-0.8MPa, ≥300L/min |

| Output | 2160-3600 pcs/hour |

| Operator | 1~2 persons |

| Function | Filling lipsticks |

20L Heating Tank adopts dual jacket layer design; The temperature and stirring speed are adjustable.

Fill 10 pcs each time with 10 nozzles.(can be changed to 12 nozzles)

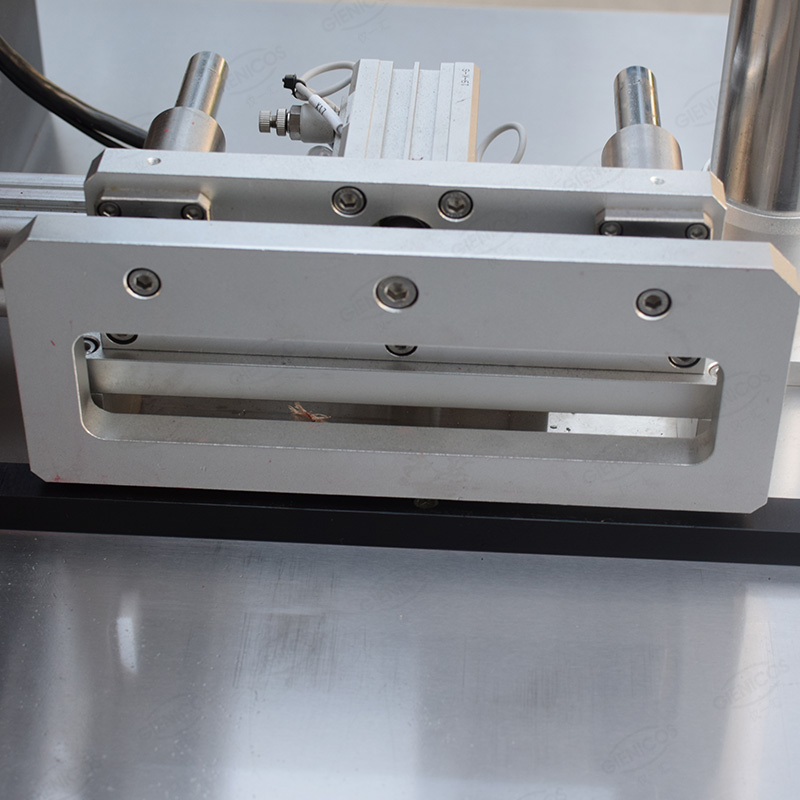

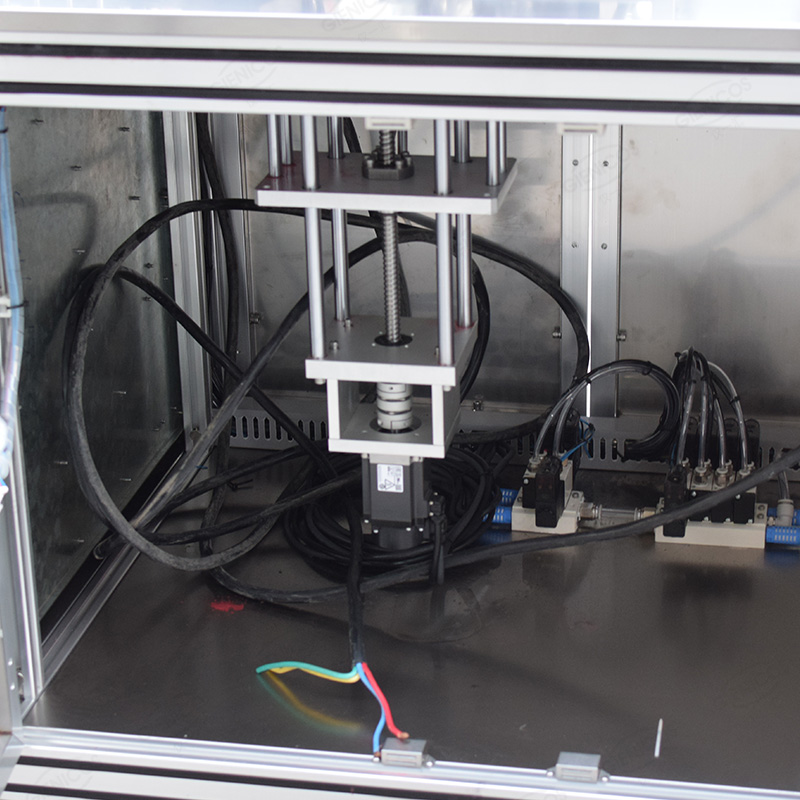

Piston filling system is driven by step motor with numerical control, rotating valve is driven by cylinder;

Stirring device is driven by motor.

Mold lifting function is driven by step motor and numerical control.

Color human-machine touch panel interface and omni bearing numerical control. Operation is easy and precise.

Filling precision is ±0.1g.

Can fill irregularity bottles.

The machine is designed with preheating system.

The design of this lipstick filling machine is compact and reasonable, the appearance is simple and beautiful, and the filling volume is easy to adjust.

This machine has the characteristics of convenient adjustment, no bottle filling, and accurate filling amount.

It makes the operation, precision error, installation and adjustment, equipment cleaning, maintenance and other aspects of the product more simple and convenient.