Reasonable price Latisse Filler - Explosion Type Automatic Nail Gel Polish Serum Filling Capping Production Line – GIENI

Reasonable price Latisse Filler - Explosion Type Automatic Nail Gel Polish Serum Filling Capping Production Line – GIENI Detail:

| Filling Method | Vacuum type |

| Filling Process | Bottle feed-auto filling-brush feed-cap feed-auto capping-convey out for packing |

| Filling Volume | 5-30ml |

| Filling precision | ±1% |

| Voltage | AC220V,1P,50/60HZ |

| Power | 2kw |

This production line can automaticly filling capping nail polish,essential oil, perfume massage oil, edible oil and other products with the similar package structure.

1 . It is monoblock type machine, with explosion proof system.

2 .Vacuum filling ensures the liquid level is always the same for all glass bottles.

3 . Capping system adopts servo motor to drive, better performance for capping efficiency.

4.The design of the adjustable fixture allows the production line to be used for Nail Polish, Essential Oil, Perfume and other cosmetics and skin care products.

This machine adopts mechanical cem system which is stable running under a coder.

It can make workers’ work convenient, safe and reduce physical labor.

By adjusting each process in a simple and easy-to-operate manner, the production line can be used to produce various cosmetics that are not used, reducing the cost of machinery and labor for cosmetics and skin care products foundries.

This production line is full automatic from bottle infeed to bottle conveyor out. One production line can replace three workers.

The production line can be changed according to the actual needs of the factory, and the degree of customization is high.

GIENICOS adopts a 5G modular remote after-sales system to help customers monitor the operation of the production line and solve after-sales problems immediately.

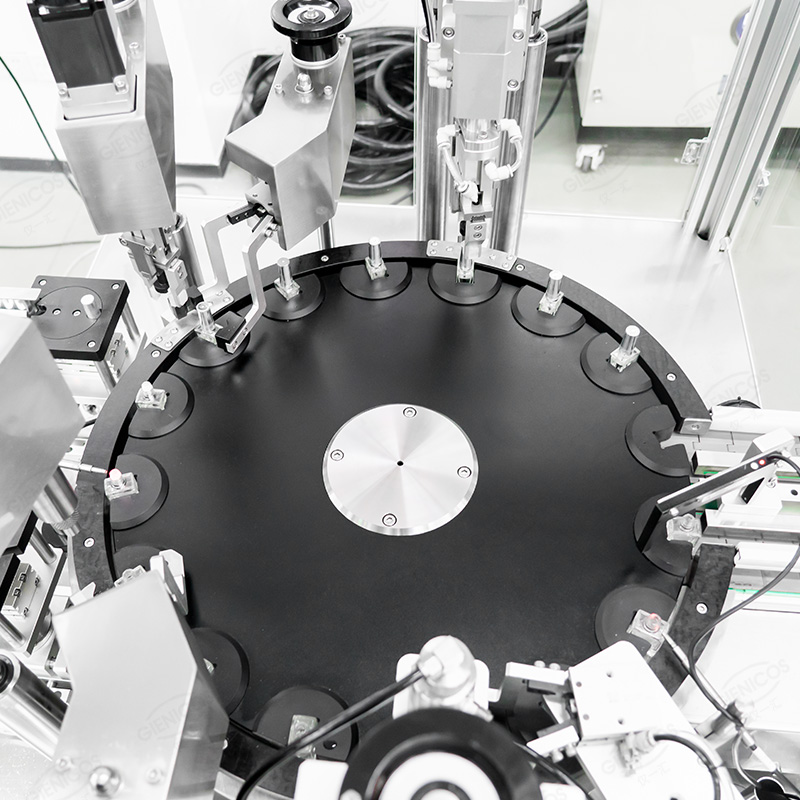

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for Reasonable price Latisse Filler - Explosion Type Automatic Nail Gel Polish Serum Filling Capping Production Line – GIENI , The product will supply to all over the world, such as: Washington, Venezuela, Egypt, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the client first principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.