With the development of the times and the improvement of people's aesthetic awareness, there are more and more types of lipsticks, some with various carvings on the surface, engraved with LOGO, and some with a layer of shiny gold powder. The lipstick machine of GIENICOS involves every step of lipstick production, which can meet the needs of customized lipstick.

Gienicos can manufacture and design lipstick machines include lipstick filling machine, lipstick cooling machine, lipstick demolding machine, lipstick production machine, and lipstick production line.

Different lipsticks require different molds to match.

Different lipsticks require different molds to match.

1. Metal Mold has waist joint line,and middle joint line

2. Half silicone ,bullet is formed by silicone mold , and it able to print logo on lipstick,cup is formed by aluminum mould (life: 30-200times) about 0.9 USD/pc

3. Full Silicone,whole lipstick is formed by silicone mold, available to print logo and without any joint line surface is perfect, it is high quality lipstick for top market.

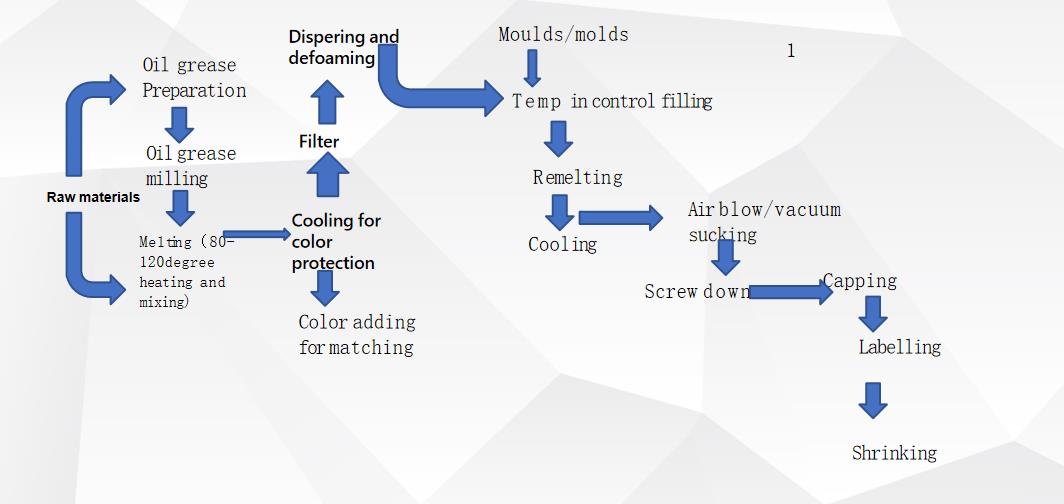

The production process of lipstick includes raw material processing, filling, cooling and forming, capping, labeling and sealing, etc. The following mind map clearly shows the whole process.

The production process of lipstick includes raw material processing, filling, cooling and forming, capping, labeling and sealing, etc. The following mind map clearly shows the whole process.

And Gienicos is a manufacturer specializing in the production and design of make-up machinery. Technical support can be provided for each link of lipstick production.

About how to choose a lipstick machine, how to choose a makeup machine, you can subscrib our youtube.

About how to choose a lipstick machine, how to choose a makeup machine, you can subscrib our youtube.

Cosmetic Machine Queen YOYO will broadcast and record for you every week.

If you have any questions about the production process of cosmetics and make-up, you can contact us.

If you have any questions about the production process of cosmetics and make-up, you can contact us.

We can support online answers, video conferences and other communication methods.

We can according to the packaging, size, shape, output, and automation requirements provided by customers. Provide customers with the most reasonable solutions and quotations. Help customers reduce production costs and increase the production cost of cosmetics.

We can according to the packaging, size, shape, output, and automation requirements provided by customers. Provide customers with the most reasonable solutions and quotations. Help customers reduce production costs and increase the production cost of cosmetics.

Post time: Dec-06-2022