Manufacturer for Packaging Machine For Lipstick - Semi Automatic Bottle Manual Two Nozzle Lip Balm Hot Filling Production Line – GIENI

Manufacturer for Packaging Machine For Lipstick - Semi Automatic Bottle Manual Two Nozzle Lip Balm Hot Filling Production Line – GIENI Detail:

| Outer dimension | 2800X1500X1890mm (LxWxH) |

| Voltage | AC220V,1P,50/60HZ |

| Power | 17KW |

| Air supply | 0.6-0.8Mpa,≥800L/min |

| Filling Volume | 20-50ML or 50-100ML by changing spares |

| Output | 20-30pcs/min.(acc.to raw materials&mold quantity) |

| Weight | 1200kg |

| Operator | 2 persons |

-

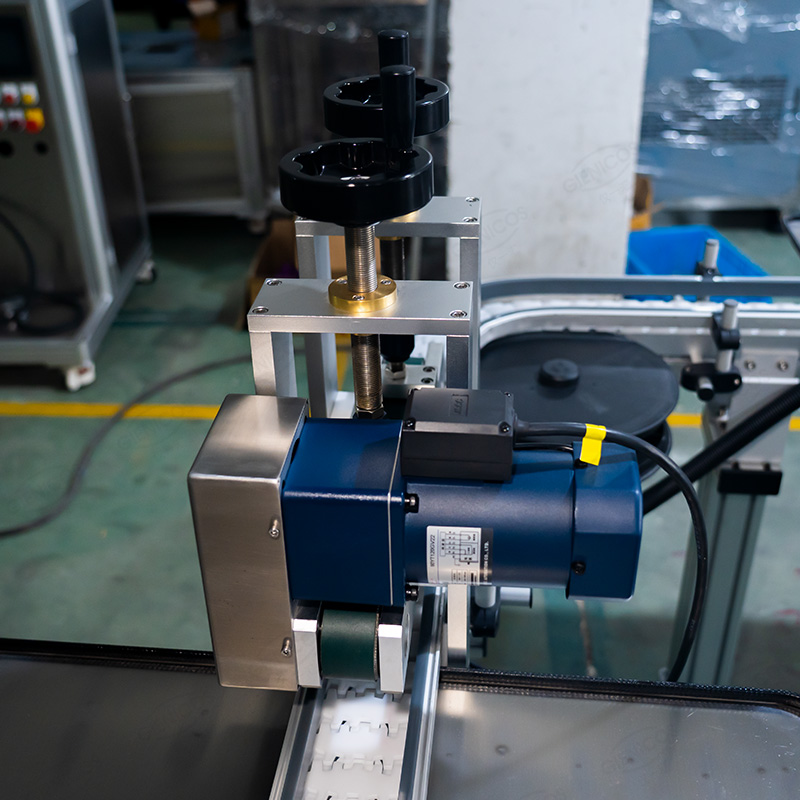

- Dual nozzle filling machine with 50L heating tank.

- Nozzles distance is adjustable.

- Piston cylinder is adjustable and changeable from 20-100ML.

- Filling is driven by servo motor.

- Cooling tunnel adopts France brand compressor.

- Conveyor VFD control.

- Low manpower cost, and energy saving.

- Simple to clean and change different colors and formula.

- Easy to operate and set parameters on touch screen.

- Highly outputting.

JHF-2 is specially designed for It is used in the production of makeup remover, concealer, deodorant cream, solid glue, lipstick, etc.

This balm machine is very easy to operate when changing batches or varieties. Save labor costs and machine maintenance costs.

Production of concealer, deodorant cream, solid glue, lipstick for almost all categories.

The machine is made of heavy-duty aluminum material, with precise design and beautiful appearance. 316L stainless steel barrel, two jackets for separate oil heating. Tanks are mixed and temperature controlled.

The stirring speed and temperature of each tank are independently controlled.

The frame made of hardened aluminum is easy to maintain.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for Manufacturer for Packaging Machine For Lipstick - Semi Automatic Bottle Manual Two Nozzle Lip Balm Hot Filling Production Line – GIENI , The product will supply to all over the world, such as: Florence, Greece, Rome, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.