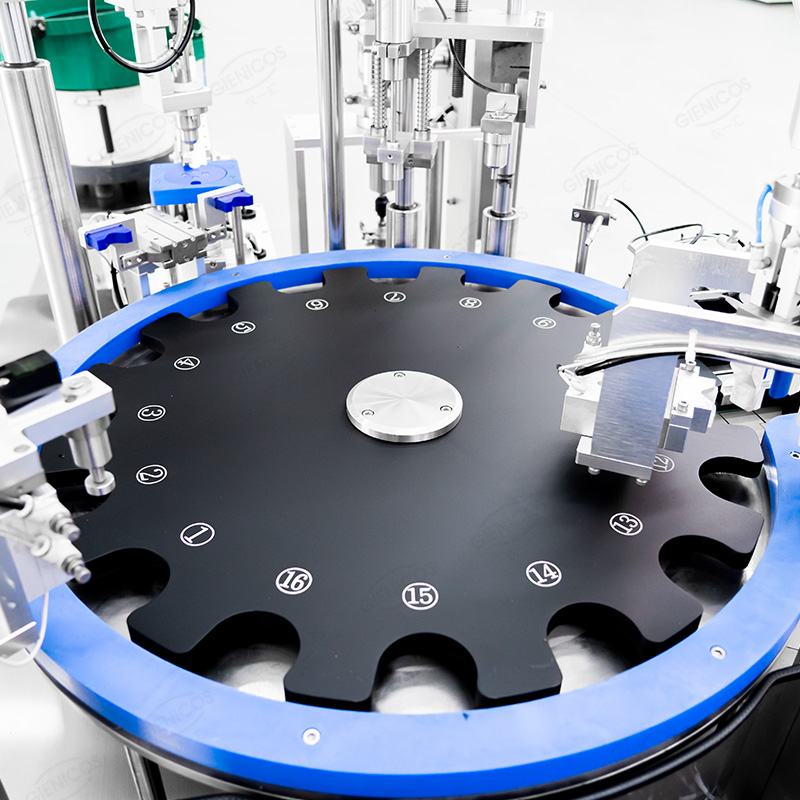

Lifting Single Nozzle Concealer Lipstick Lip Balm Filling Machine

| Voltage | 1P 220V |

| Current | 20A |

| Capacity | 25-30 pieces/min |

| Air pressure | 0.5-0.8 MPa |

| Power | 5.5KW |

| Dimensions | Layout according to conveyor belt length requirements |

| Filling volume | 0-100ML |

| Filling accuracy | ±0.1g (take 10g as an example) |

| Tank volume | 25L |

| Tank function | Heating, mixing and vacuum |

1. The filling nozzle adopts the servo lifting type, which can realize the function of rising while filling, instead of the traditional bulky lifting of the barrel, and the equipment design is more delicate

2. Quick disassembly valve body structure design, disassembly can be completed in 2-3 minutes for color change and cleaning

3. The 90-degree rotation function of the barrel is convenient for cleaning

4. The barrel has vacuum, heating and stirring functions.

5. The barrel is SUS304 material, inner layer is SUS316L material .

The filling accuracy is high, and the horizontal and vertical translation and lifting of the filling head are controlled by servo motors to ensure the overall pass rate.I

The filling nozzle is driven by servo motor, it can do static filling and bottom filling which could give the best filling result according to different material characteristics.

Made of stainless steel, it is not only beautiful but also meets the needs of corrosive liquids and food packaging equipment with high hygienic requirements. The servo system is used to quantitatively push the material, and the measurement can be digitally adjusted on the man-machine interface, and the required measurement can be set. Touch the touch screen. Up to, and can fine-tune the metering. The operation is simple, the maintenance is convenient, the labor cost is saved, and the production efficiency is higher.

粉底液转盘式充填机(新增未入册)2-300x300.png)