Hot New Products Lip Gloss Filler Machine - Hot Pouring Production Line With Remelting Conveyor Platform – GIENI

Hot New Products Lip Gloss Filler Machine - Hot Pouring Production Line With Remelting Conveyor Platform – GIENI Detail:

Hot Pouring Production Line With Remelting Conveyor Platform

| Outer dimension | 630X805X1960mm (LxWxH) |

| Voltage | AC380V,3P,50/60HZ |

| Volume | 20L,Three-layer with heating and stirring |

| Material temperature detection | yes |

| Oil temperature detection | yes |

| Discharge valve and nozzle | yes |

| temperature detection | yes |

| Weight | 150KG |

-

-

- ◆ Mixing speed&temperature adjustable by 20L three layer tank with heating and mixing function;

◆ Material can come out easily with angle 2degree inclined at tank bottom;

◆ Fast disassembling and full corner cleaning in 15mins with special designed valve(in SKD material);

◆ Output nozzle with heating function for preventing the nozzle from being blocked;

◆Material contacted parts in SUS316L,others in SUS304.

- ◆ Mixing speed&temperature adjustable by 20L three layer tank with heating and mixing function;

-

This machine is designed for flat lipbalm and other pattern lip balm.

The valve made of special material has high purity, better toughness, uniform structure, good high temperature strength, toughness and high temperature fatigue resistance, and can withstand sudden temperature changes.

Since the lipstick will form a paste after cooling, it is not conducive to the accuracy of filling. So we use a heating system on the filling head. It ensures the smoothness of the lipstick production line during the filling process.

Tanks with slopes are easier to clean and refuel. And towards unity, the security is stronger.

The link of this machine adopts special design and technology, and it is very convenient to disassemble. It is a good thing for cleaning and moving the machine.

It is suitable for cosmetics custom factories with relatively fast R&D and product replacement.

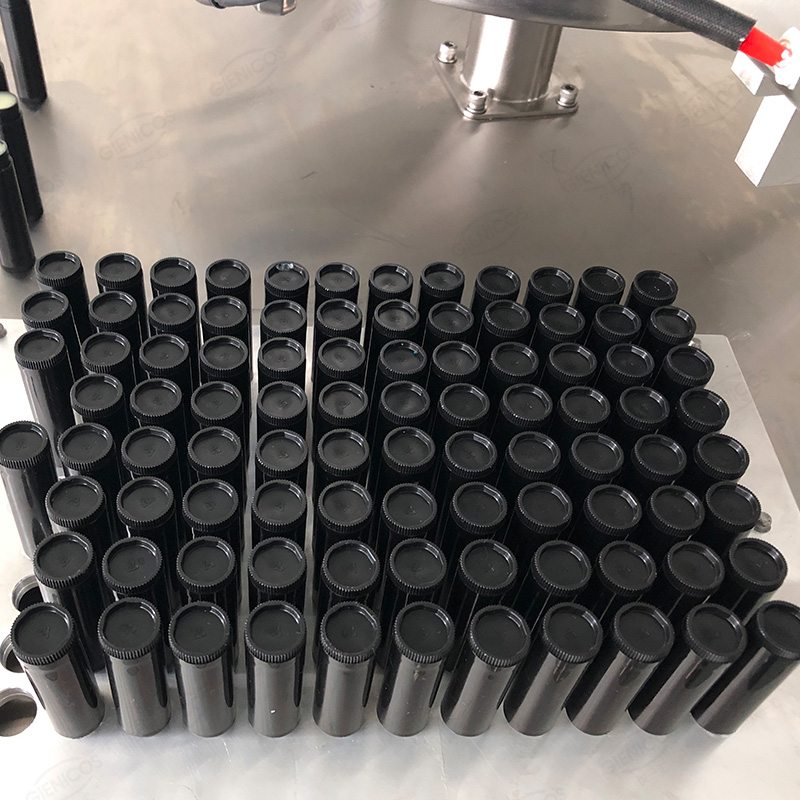

Product detail pictures:

Related Product Guide:

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Hot New Products Lip Gloss Filler Machine - Hot Pouring Production Line With Remelting Conveyor Platform – GIENI , The product will supply to all over the world, such as: Mumbai, Wellington, Sacramento, With a wide range, good quality, reasonable prices and stylish designs, our items are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.