Horizontal Lipstick Sleeve Shrink Labeling Machine

| Power Supply | AC 380V,3 phase,50/60HZ,15KW |

| Target Products | Slim and long objects such as Lipstick, mascara, lipgloss, pencil box, oil bottle, etc |

| Range of the product size | 10*10mm—25*25mm25*25mm—45*45mm (Can be customized for other size) |

| Film Material | PE, PVC, OPS, PET |

| Film Thickness | 0.035-0.045mm |

| Film Roll Core Diameter | 100-150MM |

| Film Heating Temp. | Up to Max 200 ℃ |

| Labeling Speed | 100pcs/min |

| Film Cut Precision | ±0.25MM |

| Sensor | Keyence (Japan) |

| Safety Cover | Yes, with air spring and brake. |

-

-

-

-

-

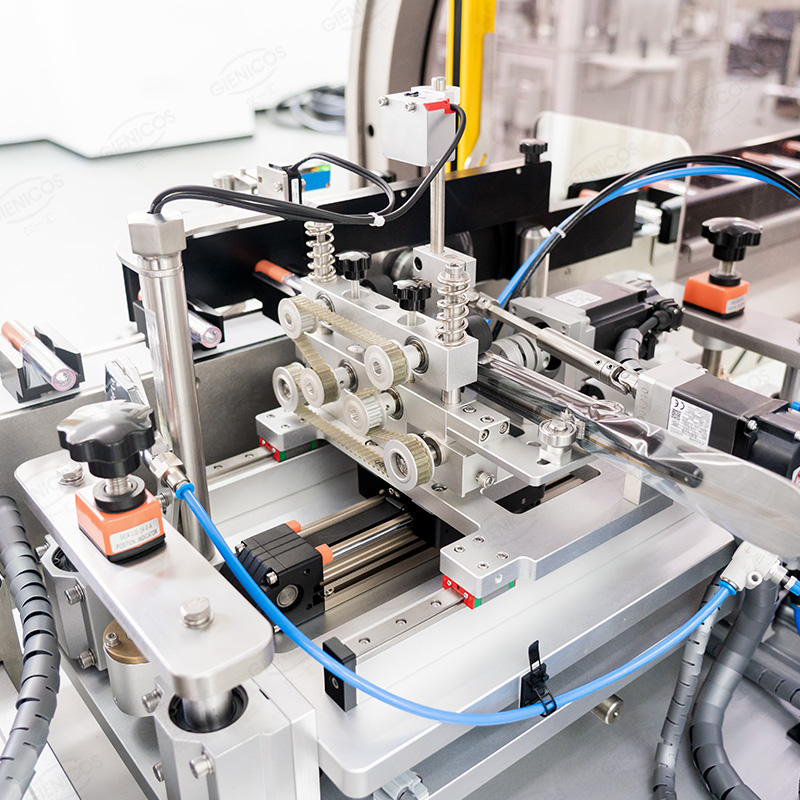

- Servo control the film inserting station which is a tracking design, it increases the production speed and the accuracy of inserting rate is highly improved. Film is automatically feed from a roller film loading system.

- Horizontal type design gives the sleeve shrinking able to work for small size bottles/boxes compared with vertical type. Compact design with all function on one machine save the customers room space and transportation cost. It has wing style safety cover mounted with air spring for easy open and close, meanwhile it also has a brake on the air spring for protect the cover from being closed suddenly.

-

-

-

-

This machine adopts full Servo control system for the film cutting results in high precision at ±0.25mm. The film cutting system adopts single piece round cutting knife ensures flat cutting surface and non burrs.

The shrinking tunnel is inner mounted to the machine after film wrapping. Special heating-while-rotating conveyor assist the heating is evenly to be done at bottles’ surface so that there is no air bubble happens. Meanwhile the heating oven is able to be auto lifted up when machine stops and it turns back to prevent conveyor from being burned.

This machine also gives a shaping function at the end of shrinking tunnel, it is very smart design for those square bottles or boxes which can flat process the two ends

- High speed production rate meets the demands for all cosmetic factory. It can be used as a single machine with manual load bottles one by one, but also can be worked with a automatic robot loading system to fullfil the whole process automatically.

Flexible design for different size bottles and boxes by fast changing the spare parts, which is the most favorite for OEM/ODM manufacturer. PLC and touch screen helps the adjustment more easier and convenient.

Tracking type film wrapping with single piece style round knife are both the highlights for this machine, customers are happy with the wrapped bottles/boxes without any burrs and the cutting edge is really flat when you touch by finger.

GIENICOS gives fast support in 24hours and able to offer face-to-face commissioning & training if needed.

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)