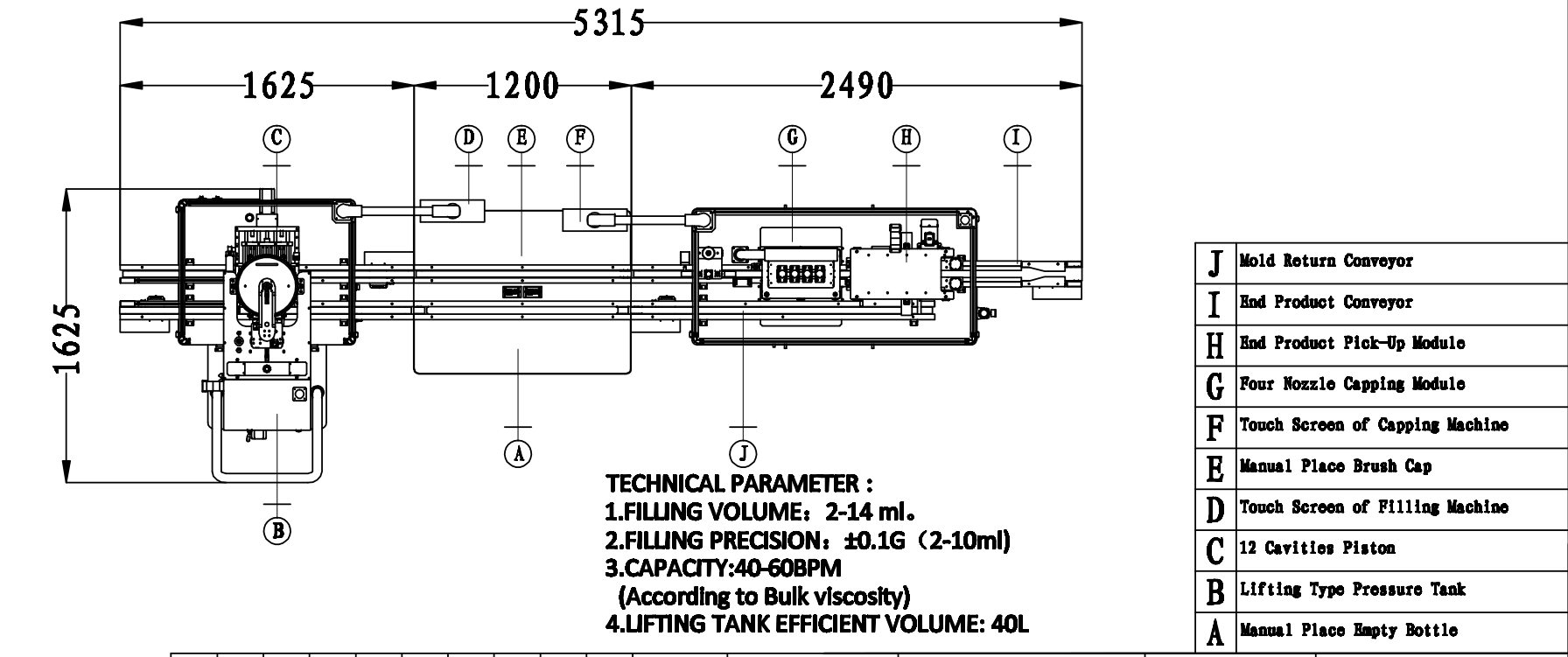

High Speed Mascara Filling Capping Machine

TECHNICAL PARAMETER

TECHNICAL PARAMETER

High Speed Mascara Filling Capping Machine

| Filling Volume Range | 2-14ml |

| Filling Accuracy | ±0.1G |

| Tank Volume | 40L, with pressure piston |

| Tank Design | Mobile, auto lift up/down |

| Filling Nozzles | 12pcs |

| Capping Head | 4pcs, servo driven |

| Air supply | 0.4Mpa~0.6Mpa |

| Output | 60~84pcs/min |

| Module design | Can add auto wipers feeding and robot loading system later |

Features

Features

- 20L SUS304 tank, sanitary materials.

- Motor-driven piston filling system, accurate filling.

- Fill 12 pieces each time.

- The filling mode can choose static filling or drop filling.

- The filling nozzle has a backflow function to reduce bottle mouth pollution.

- With container detection system, no container, no filling.

- Servo capping system is adopted, and all parameters such as torque and speed are set on the touch screen.

- The capping jaws can be adjusted according to the height of the container, or can be made by the shape of the bottle cap.

- High Speed production

- Mounted with U-shape Holder Circulation Running Design suits for batch production in OEM/ODM factory

- Easy operation

- Servo driven Capping, torque adjustable without scratching cap surface.

Application

Application

This machine is widely used for filling mascara. It can work with automatic inner wiper feeding to effect output. It can be also worked with robot to achieve bottle loading automatically.

Why choose us?

Why choose us?

The filling valve is controlled by a piston valve, and the filling accuracy is ±0.1; the filling volume can be adjusted within 2-14ml, and the filling can be adjusted within 48-60 pieces/min.

GENIECOS focus on research and manufacture makeup machines from 2011.It is one of the earliest manufacturers in China to start the automatic filling of mascara and lip gloss.

The design and components of our machines meet CE certification requirements.

In terms of production efficiency, safety and other aspects, the degree of humanization and practicability are very strong.