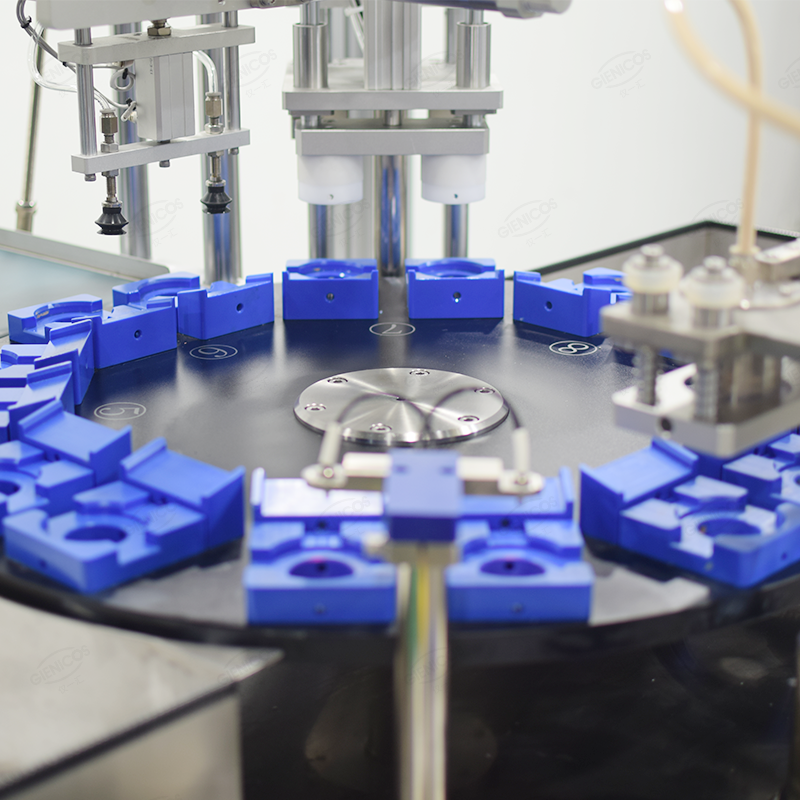

High Precision Air Cushion CC Cream Rotary Filling Machine with Auto Pickup

| Powder case size | 6cm(can be customized according to customer’s requirements) |

| Max filling volume | 20ml |

| Voltage | AC220V,1P,50/60HZ |

| Filling precision | ±0.1G |

| Air Pressure | 4~7kgs/cm2 |

| Outer dimension | 195x130x130cm |

| Capacity | 20-28pcs/min (according to raw material’s characteristics and sponge density) |

-

-

-

-

-

- ♦ Material Tank in 15L is made of sanitary materials SUS316.

♦ Filling and lifting adopt servo motor driven, convenient operation and precise dosing.

♦ Two pieces to fill each time, can form single color/double colors. (3 color or more are customized).

♦ Different pattern design can be achieved by changing different filling nozzle.

♦ PLC and touch screen adopts Siemens brand.

♦ Cylinder adopts Airtac brand.

- ♦ Material Tank in 15L is made of sanitary materials SUS316.

-

-

-

-

- Increased Efficiency: GIENICOS CC cream filling machine can fill containers much faster and with greater accuracy than manual filling methods, which can increase overall production efficiency.Consistent Filling:GIENICOS CC cream filling machine, you can achieve consistent filling levels across all containers, ensuring that each product meets the same high-quality standards.

Reduced Waste: With accurate and precise filling, GIENICOS CC cream filling machine can help to reduce product waste, which can save money and improve sustainability.

Improved Safety: Using a filling machine can reduce the risk of product contamination and improve worker safety by minimizing the need for manual handling of the product.

Versatility: GIENICOS CC cream filling machine can be used to fill a wide range of container sizes and shapes, making it a versatile solution for different product lines.

Cost-effective: Over time, the use of a filling machine can result in cost savings due to increased production efficiency and reduced waste.

GIENI双色气垫拉花充填机-全自动控制-300x300.png)