factory low price Essential Oil Filling And Capping Machine - Turnkey Project Essential Oil 4Nozzle Filling Capping Labeling Production Line – GIENI

factory low price Essential Oil Filling And Capping Machine - Turnkey Project Essential Oil 4Nozzle Filling Capping Labeling Production Line – GIENI Detail:

| Voltage | 1P/3P 380V/220V |

| Filling Nozzles | 4 |

| Power | 2.5KW |

| Current | 12A |

| Output | 1800-2400 bottle/hour |

| Air pressure | 0.5-0.8 MPa |

4Nozzle Filling production line is applied for essential oil, face serum, dripper bottle oil etc. It could reach speed at 40pcs/min.

1. The whole line is fully automatic, 1-2 operator is enough to monitor the line and add empty bottles.

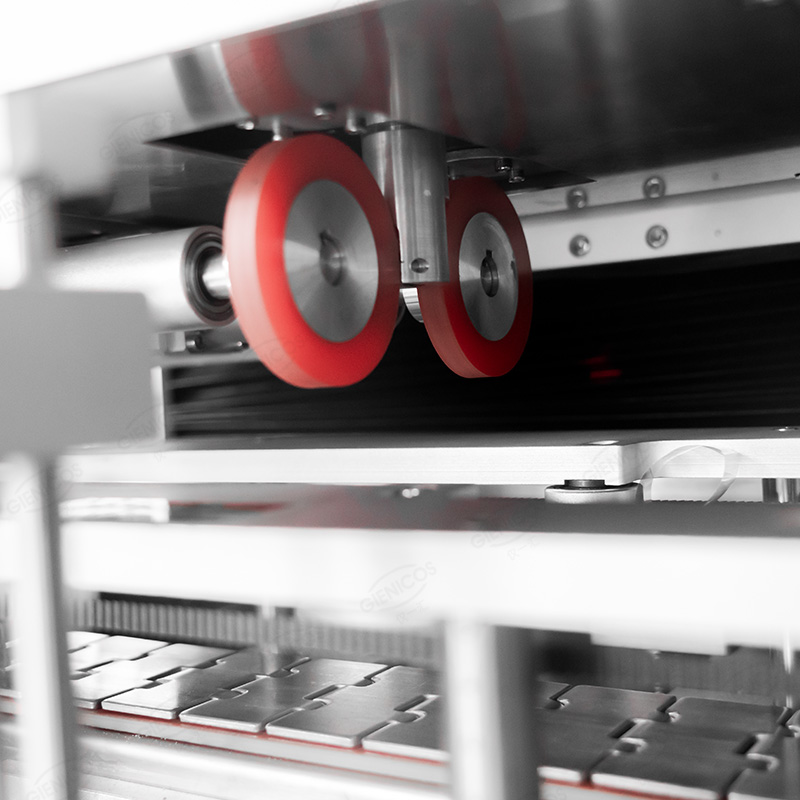

2. 4nozzle filling and capping machine adopts rotary design, full SUS frame and safety door meets GMP standard.

3. Piston filling driven by servo motor results in high filling precision.

4. Filling nozzles are able to be lifted up and down which is also driven by servo motor.

5. Flat caps or dripper caps are both able to be sorted and loaded automatically.

6. Capping system driven by servo motor is self-designed by GIENICOS, the rotary speed/torque are all adjustable.

7. Induction sealing machine adopts water cooling circulation system, high efficiency.

8. High speed sleeve shrink labeling machine is able to do the neck shrink for flat cap.

9. Round bottle labelling machine is well made to do half-round label or full-round label stick on.

10. Buffer rotary table designed after filling and capping machine is to make sure non-stop production when operator replace labels during production.

1. The whole line is fully automatic, 1-2 operator is enough to monitor the line and add empty bottles.

2. 4nozzle filling and capping machine adopts rotary design, full SUS frame and safety door meets GMP standard.

3. Piston filling driven by servo motor results in high filling precision.

4. Filling nozzles are able to be lifted up and down which is also driven by servo motor.

5. Flat caps or dripper caps are both able to be sorted and loaded automatically.

6. Capping system driven by servo motor is self-designed by GIENICOS, the rotary speed/torque are all adjustable.

7. Induction sealing machine adopts water cooling circulation system, high efficiency.

8. High speed sleeve shrink labeling machine is able to do the neck shrink for flat cap.

9. Round bottle labelling machine is well made to do half-round label or full-round label stick on.

10. Buffer rotary table designed after filling and capping machine is to make sure non-stop production when operator replace labels during production.

Product detail pictures:

Related Product Guide:

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for factory low price Essential Oil Filling And Capping Machine - Turnkey Project Essential Oil 4Nozzle Filling Capping Labeling Production Line – GIENI , The product will supply to all over the world, such as: New York, Paraguay, Peru, We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

Speaking of this cooperation with the Chinese manufacturer, I just want to saywell dodne, we are very satisfied.