Essential Massage Medicine Oil Filling Capping Labeling Production Line

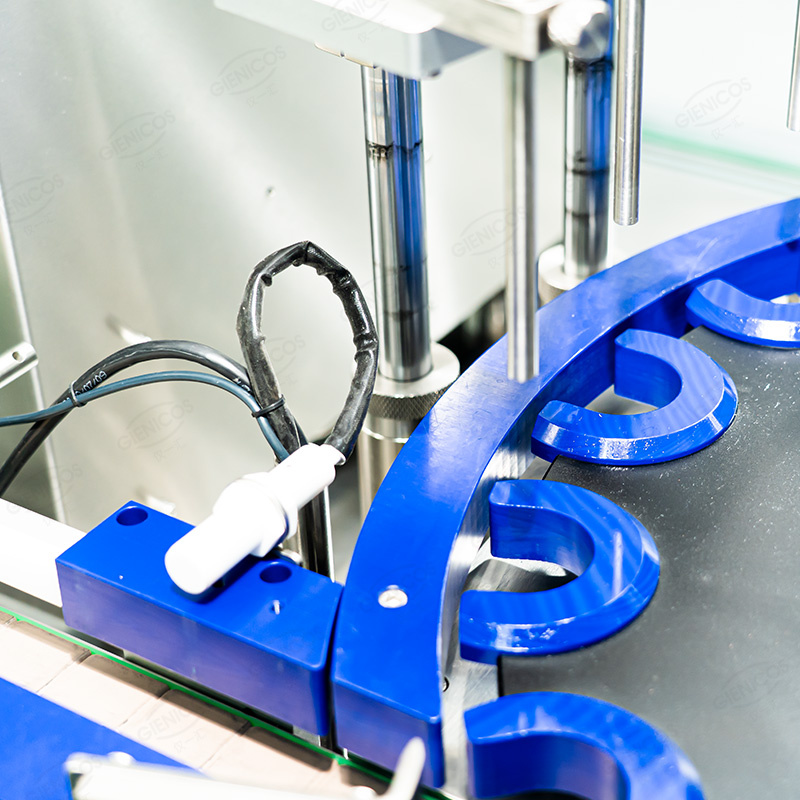

1. The photoelectric sensor detects whether there is an empty bottle on the main rotary table, and sends the detection signal to the computer to control the filling, corking and capping of bottles, it will not filling, corking and capping without bottles.

2. Use fixed cup holder with magnetic design, allows operator replace them easily.

3. Use servo piston filling with high filling accuracy.

4. Use vibrating cover trimmer to trim the brush. (optional device)

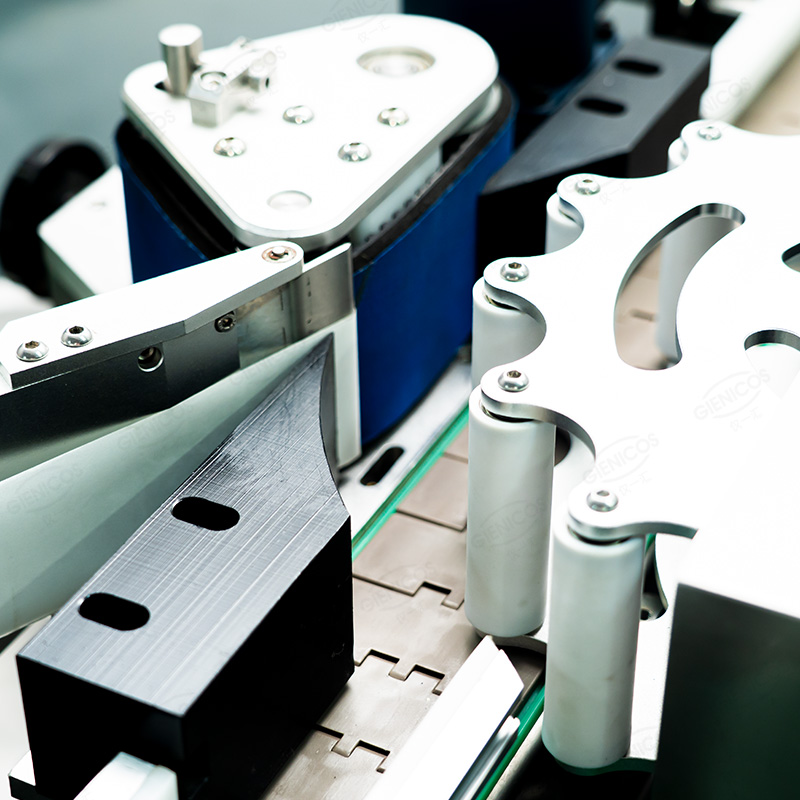

5. Use the manipulator to automatically pressurize the outer cover and cooperate with the guide mechanism, with accurate positioning and high efficiency.

6. Use the servo motor to screw the cover, and the torque is adjustable without damaging the cover.

It has the functions of no filling without bottle and no capping without cap. It has the advantages of simple operation and convenient adjustment.

The machine runs smoothly without fragments. Simple operation and accurate filling. It is easy to operate and has low requirements for workers. Strong stability, seldom break down.

The 5G modular after-sales service system is applied to the production line, allowing the technology to accurately monitor the operating status of the machine. When the machine fails or is damaged due to operational errors, technicians can immediately find out where the failure occurred.

99、全自动液体灌装旋盖贴标生产线-300x300.png)