Competitive Price for Cc Cream Machine - Cosmetic Hot Cold Filling Cooling Production Line – GIENI

Competitive Price for Cc Cream Machine - Cosmetic Hot Cold Filling Cooling Production Line – GIENI Detail:

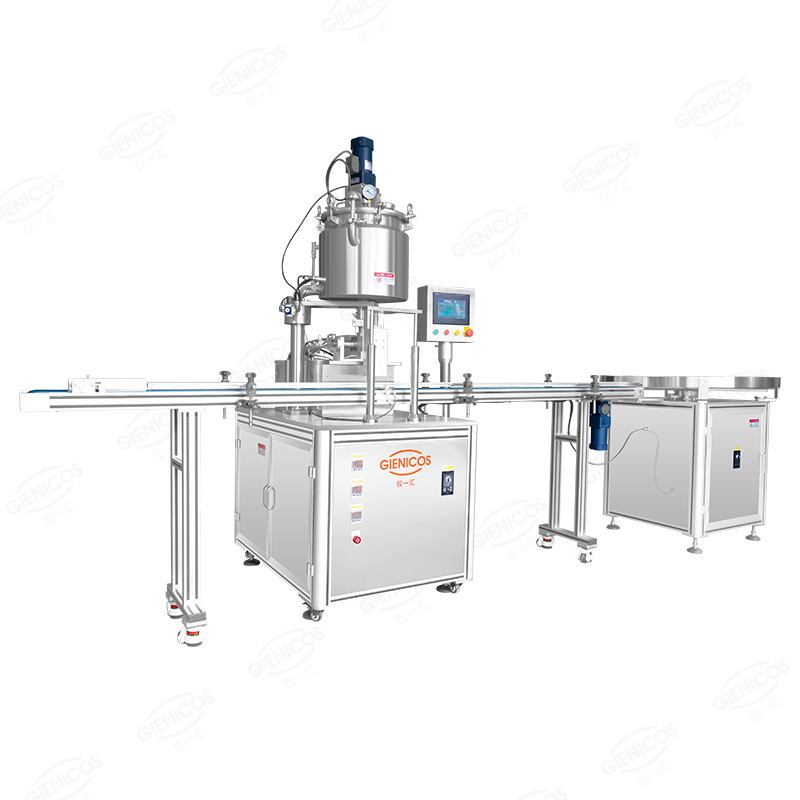

| Filling Nozzle | 1 nozzle, bottom filling, and static filling;Servo driven lift up-down;With warm keeping function |

| Filling Tank Volume | 25Litre |

| Filling Tank Material | 2 layers tank with heating/stirring/vacuum functions, outer layer: SUS304, inner layer: SUS316L, comply with GMP standard |

| Filling Tank Temp. Control | Bulk temperature detection, heating oil temperature detection, filling nozzle temperature detection |

| Filling Type | suitable for both cold & hot filling, filling volume up to 100ml |

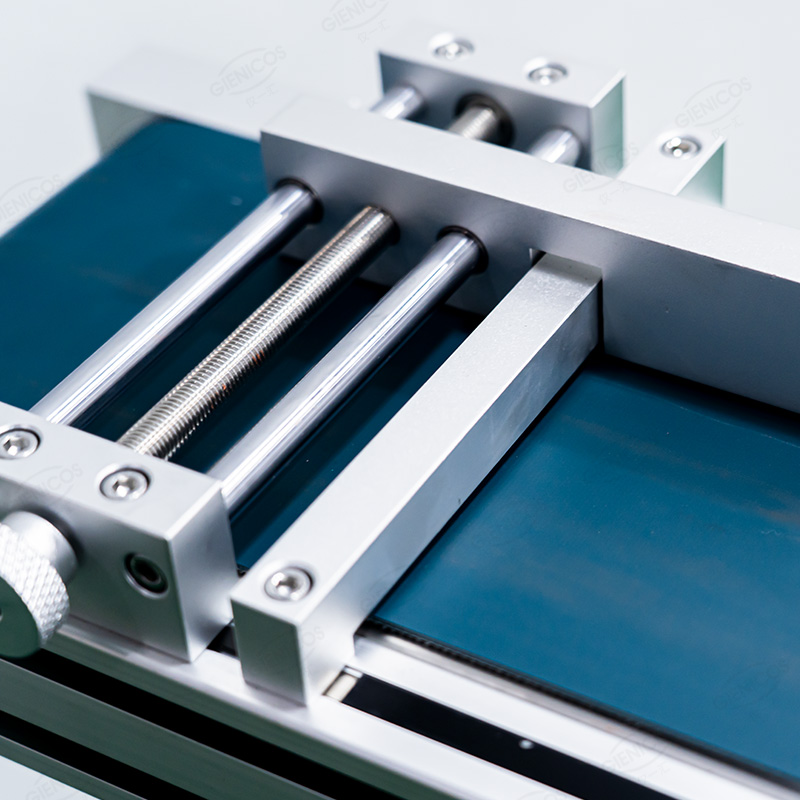

| Filling Valve | new design,90S QUICK DISASSEMBLING TYPE, you can select different piston cylinder to fulfill varies filling volume, easy and fast to changeover |

Hot filling for high viscosity products, like lipstick in pan, lip balm, shea butters, foundation cream, concealer, etc;

Cold filling for great fluids, such as lotion, shampoo, and other oily products.

1. The filling precision is accurate. This machine uses a servo motor to drive the piston for filling. Equipment accuracy error is less than ±0.1G.

2. This machine is equipped with our specially designed thermal insulation system, without oil circulation system, and can realize the function of uniform constant temperature filling of all parts. At the same time, the machine adopts the filling nozzle plugging technology, which can realize the function of large-dose filling of hot-filled products.

3. This machine can replace piston pump for different volumes, and adopts a quick-release design, which is clear and convenient.

5. This machine adopts servo motor to realize the way of filling and rising.

6. Flexible and strong. This machine is suitable for the quick production change function of different specifications of packaging materials, and adopts a modular design, which can quickly disassemble the valve body cleaning function. (Disassembly time for cleaning is about 1-2 minutes)

6. This machine is equipped cooling tunnel with conveyor, the speed is adjustable. it adopts France brand compressor of 7.5P, the cooling temperature could reach max. -15 to -18 degree. With our design, the compressor on top to speed the heat exchange rate.

7. With rotary collection table.

This machine has a strong ability to be modified. The filling and cooling machine can be purchased and used separately, and can be deployed according to the production needs of the cosmetics factory.

The disassembly and assembly of this machine is very convenient. Whether it is to replace the barrel or the conveyor between the machines in the production line, the quick-release design makes the production line more flexible. For cosmetics OEM factory, it is often necessary to replace materials and packaging. This machine is a very good choice.

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for Competitive Price for Cc Cream Machine - Cosmetic Hot Cold Filling Cooling Production Line – GIENI , The product will supply to all over the world, such as: Gabon, Amman, Ireland, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

Managers are visionary, they have the idea of mutual benefits, continuous improvement and innovation, we have a pleasant conversation and Cooperation.