12 Nozzle Lip Balm Hot Filling Manufacture Line

| Outer dimension | 1650*1050*2200MM (LxWxH) |

| Voltage | AC220V,1P,50/60HZ |

| Power | 3.8KW |

| Air pressure | 4~6 kg/cm2 |

| Output | 6-10moulds/min(72~120pcs), According to the size of vessel . |

| Power supply(filler) | AC220V, 1P, 50/60HZ |

| Power Supply(Cooler) | AC380V, 3P, 50/60HZ |

| Dosing Method | Gear pump |

| Tank | 20L or customized |

| Dual temp | Control for both heating oil and material bulk. |

| Filling Range | Unlimited |

| filling accuracy | ±0.1G |

| Cooling Capacity | 5P |

| Reheating Method | Lamb Heat |

-

-

- ◆ 20L Heating tank adopts dual jacket layer design. The temperature and stiring speed are adjustable.

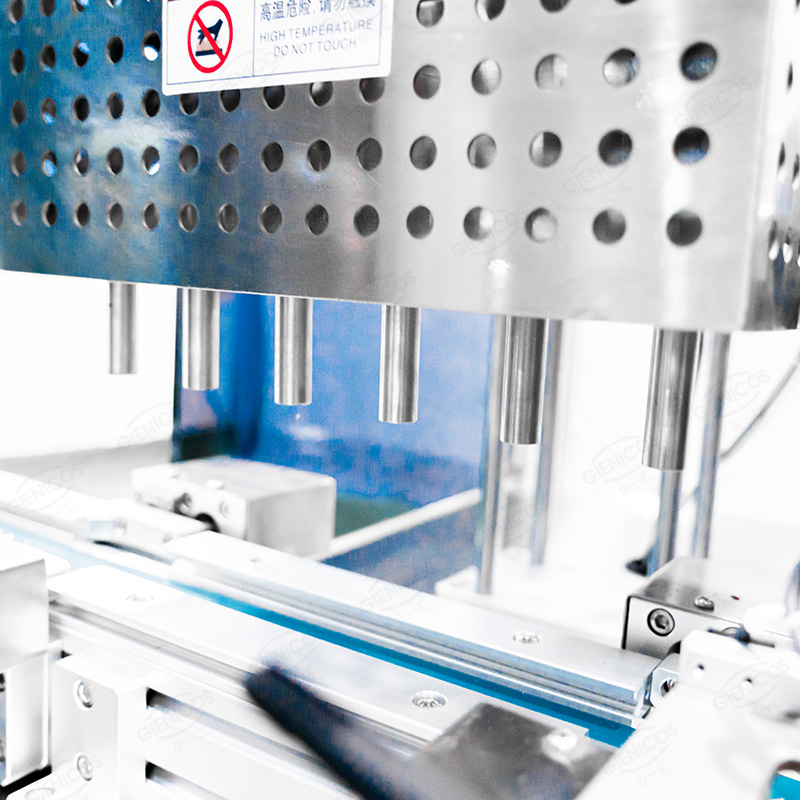

◆ Fill 12 pcs each time with 10 nozzles.(can be switched into 12 nozzles).

◆ Piston filling system is driven by servo motor with numerical control. rotary valve is driven by air cylinder.

◆ Stirring device is driven by motor.

◆ Mould lifting function is driven by step motor and numerical control.

◆ Color human-machine touch panel interface and omnibearing numerical control. Operation is easy and precise.

◆ Filling precision is ±0.1g.

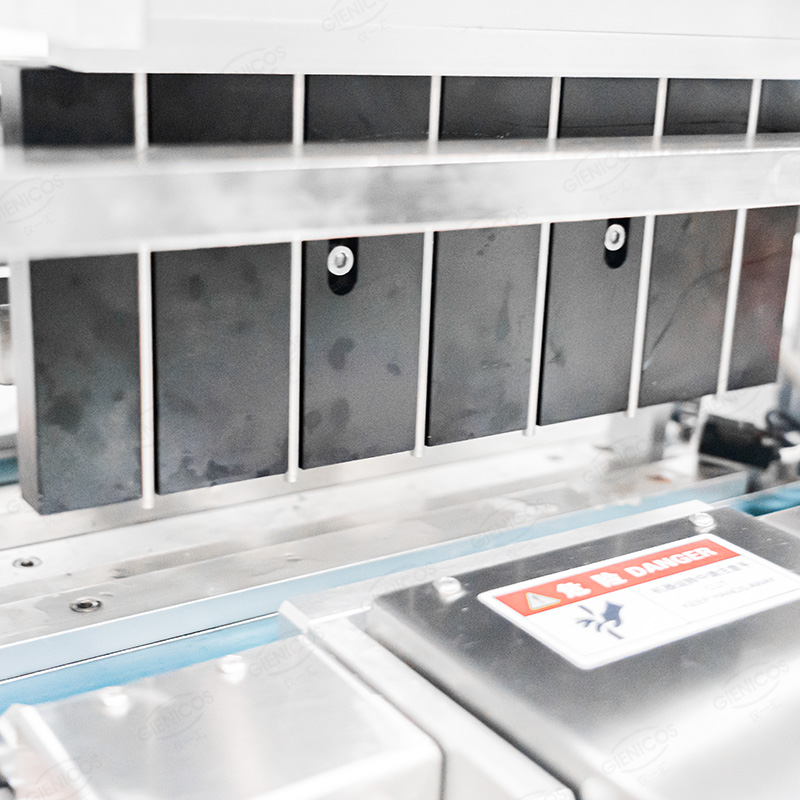

◆ Can fill irregularity bottles.

- ◆ 20L Heating tank adopts dual jacket layer design. The temperature and stiring speed are adjustable.

-

This machine has a simple and beautiful appearance and a small footprint.The color of protective shield is changeable.

Various irregular bottles can be filled to adapt to the change of products and packaging.

The man-machine interface can be customized according to customer requirements, to meet the work requirements of different customers, to meet customer needs, tailor-made work efficiency.

润唇膏-300x300.png)